This client contacted me interested in replacing the very dated tile on her fireplace, island, and kitchen backsplash.

When we started demo, it became clear very quickly, that the drywall behind the tile was going to have to come out as well. All surfaces were demoed down to the studs, and new backerboard was installed. I prefer to do this since it gives a nice, flat, and clean surface for installation.

I started with the backsplashes, a larger marble subway tile. The client and I agreed on a 50% offset pattern for the layout. I chose to do a fingerlace pattern when wrapping into the window. I usually trim out my projects with a metal profile, but I felt it just didn’t fit with this classic tile.

I then moved on to the island and fireplace. For this area the client chose a 12x24” porcelain tile that had a carerra marble pattern to it. For this portion of the project, I used the Schluter Jolly trim on the exposed edges. I chose to go with a straight lay pattern for this layout. A lot of people prefer a 50% offset pattern for this type of tile, what they may not know, is this layout is often not recommended by the manufacturer. Many manufacturers print the recommended layouts right on the tile packaging.

When I demoed the fireplace, i discovered a hodgepodge disaster. Brick, concrete, and framing held on by glue. My assistant and I started, affectionately, referring to it as the “frankenfireplace”. How this thing held up those tiles, I will never know. I added framing members in various areas using a strong adhesive and ramset drive pins. This gave me more framing to attach my backerboard to.

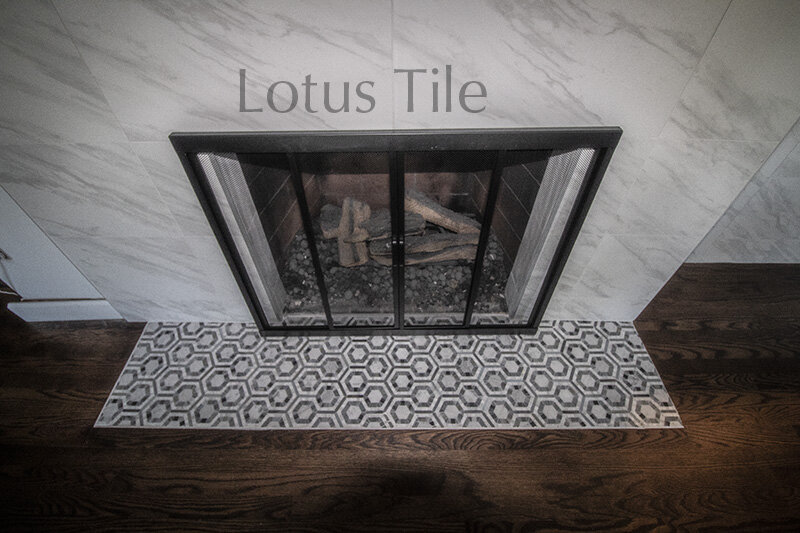

For the hearth, the client chose a beautiful marble mosaic. When we demoed the old hearth, we found a crumbly mortar bed a few inches thick. After removing this, it left the sub floor sitting well below the hardwood flooring. I used a self leveling concrete to raise the height of the subfloor so that the tile would sit flush with the wood flooring after installation.

There were some minor challenges that presented themselves throughout the project, but that is the nature of construction, it’s all in how you handle it, and there is always a solution. This is one of my favorite projects to date, and I could not have asked to work for a more wonderful family!